论文2016阅读次数 [991] 发布时间 :2016-04-14 15:34:37

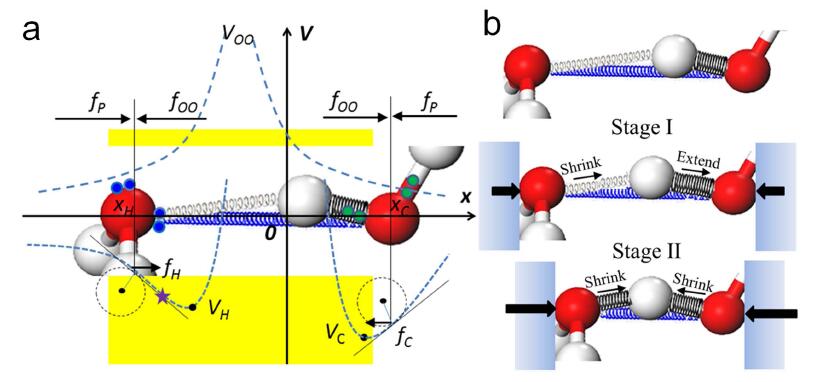

9. Hydrogen-bond potential for ice VIII-X phase transition

Scientific Reports 6(2016), 37161

Xi

Zhang, Shun Chen & Jichen Li

Repulsive

force between the O-H bonding electrons and the O:H nonbonding pair within

hydrogen bond (O-H:O) is an often overlooked interaction which dictates the

extraordinary recoverability and sensitivity of water and ice. Here, we present

a potential model for this hidden force opposing ice compression of ice VIII-X

phase transition based on the density functional theory (DFT) and neutron scattering

observations. We consider the H-O bond covalent force, the O:H nonbond

dispersion force, and the hidden force to approach equilibrium under

compression. Due to the charge polarization within the O:H-O bond, the

curvatures of the H-O bond and the O:H nonbond potentials show opposite sign before

transition, resulting in the asymmetric relaxation of H-O and O:H (O:H

contraction and H-O elongation) and the H+ proton centralization towards phase

X. When cross the VIII-X phase boundary, both H-O and O:H contract slightly.

The potential model reproduces the VIII-X phase transition as observed in

experiment. Development of the potential model may provide a choice for further

calculations of water anomalies.

overlooked interaction which dictates the

extraordinary recoverability and sensitivity of water and ice. Here, we present

a potential model for this hidden force opposing ice compression of ice VIII-X

phase transition based on the density functional theory (DFT) and neutron scattering

observations. We consider the H-O bond covalent force, the O:H nonbond

dispersion force, and the hidden force to approach equilibrium under

compression. Due to the charge polarization within the O:H-O bond, the

curvatures of the H-O bond and the O:H nonbond potentials show opposite sign before

transition, resulting in the asymmetric relaxation of H-O and O:H (O:H

contraction and H-O elongation) and the H+ proton centralization towards phase

X. When cross the VIII-X phase boundary, both H-O and O:H contract slightly.

The potential model reproduces the VIII-X phase transition as observed in

experiment. Development of the potential model may provide a choice for further

calculations of water anomalies.

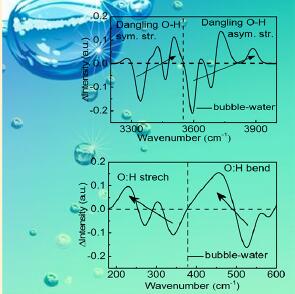

8. Nanobubble

Skin Supersolidity

Langmuir 32(2016) , 11321−11327

Xi Zhang, Xinjuan Liu, Yuan Zhong, Zhaofeng Zhou, Yongli Huang, and Chang Q. Sun*

Water

nanobubbles manifest fascinatingly higher mechanical strength, higher thermal

stability, and longer lifetime than macroscopic bubbles; thus, they provide an

important impact in applications in the biomedical and chemical industries.

However, a detailed understanding of the mechanism behind these mysteries of

nanobubbles remains a challenge. Consistency between quantum computations and

Raman spectrometric measurements confirmed our predictions that a nanobubble

skin shares the same supersolidity

with molecular clusters, skins of bulk water, and water droplets because of molecular

undercoordination (fewer than four nearest molecular neighbors). Molecular undercoordination

(coordination number Zcluster < Zsurface < Zbubble < Zbulk = 4)

shortens/extends the H−O/O:H bond and stiffens/softens its corresponding stretching phonons, whose

frequency shift is proportional to the square root of the cohesive energy and inversely

proportional to the segmental length. The strongly polarized O:H−O bond slows the molecular dynamics and

increases the viscosity. The freezing temperature is lowered by the softened

O:H bond, and the melting temperature is enhanced by the stiffened H−O bond. Therefore, the supersolid skin makes the

nanobubbles thermally more stable, less dense, and stiffer and slows the

dynamics of their molecular motion.

macroscopic bubbles; thus, they provide an

important impact in applications in the biomedical and chemical industries.

However, a detailed understanding of the mechanism behind these mysteries of

nanobubbles remains a challenge. Consistency between quantum computations and

Raman spectrometric measurements confirmed our predictions that a nanobubble

skin shares the same supersolidity

with molecular clusters, skins of bulk water, and water droplets because of molecular

undercoordination (fewer than four nearest molecular neighbors). Molecular undercoordination

(coordination number Zcluster < Zsurface < Zbubble < Zbulk = 4)

shortens/extends the H−O/O:H bond and stiffens/softens its corresponding stretching phonons, whose

frequency shift is proportional to the square root of the cohesive energy and inversely

proportional to the segmental length. The strongly polarized O:H−O bond slows the molecular dynamics and

increases the viscosity. The freezing temperature is lowered by the softened

O:H bond, and the melting temperature is enhanced by the stiffened H−O bond. Therefore, the supersolid skin makes the

nanobubbles thermally more stable, less dense, and stiffer and slows the

dynamics of their molecular motion.

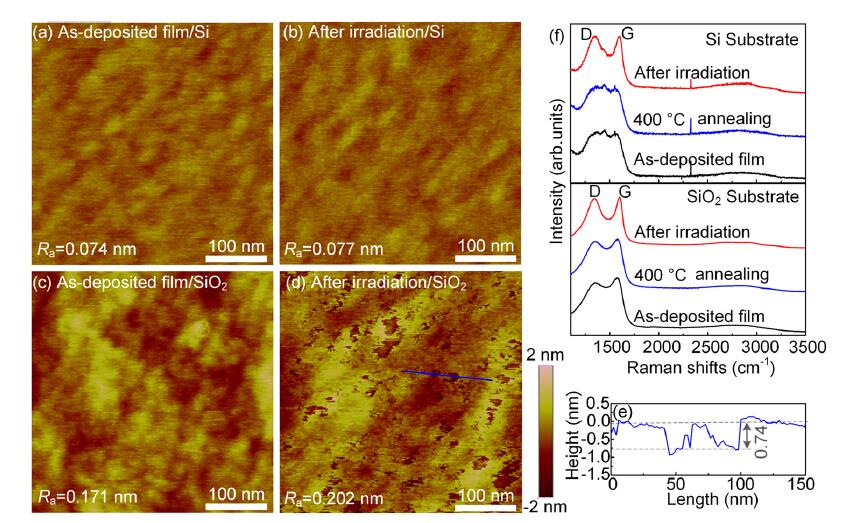

7. Low

energy electron irradiation induced carbon etching: Triggering carbon film reacting

with oxygen from SiO2 substrate

Applied Physics Letters 109(2016), 053104

Cheng

Chen,Chao Wang, and Dongfeng Diao

We

report low-energy (50–200 eV) electron irradiation induced etching of thin

carbon films on a SiO2 substrate. The etching mechanism was interpreted

that electron irradiation stimulated the dissociation of the carbon film and

SiO2, and then triggered the carbon film reacting

with oxygen from the SiO2 substrate. A requirement

for triggering the etching of the carbon film is that the incident electron

penetrates through the whole carbon film, which is related to both irradiation

energy and film thickness. This study provides a convenient electron-assisted

etching with the precursor substrate, which sheds light on an efficient pathway

to the fabrication of nanodevices and nanosurfaces.

mechanism was interpreted

that electron irradiation stimulated the dissociation of the carbon film and

SiO2, and then triggered the carbon film reacting

with oxygen from the SiO2 substrate. A requirement

for triggering the etching of the carbon film is that the incident electron

penetrates through the whole carbon film, which is related to both irradiation

energy and film thickness. This study provides a convenient electron-assisted

etching with the precursor substrate, which sheds light on an efficient pathway

to the fabrication of nanodevices and nanosurfaces.

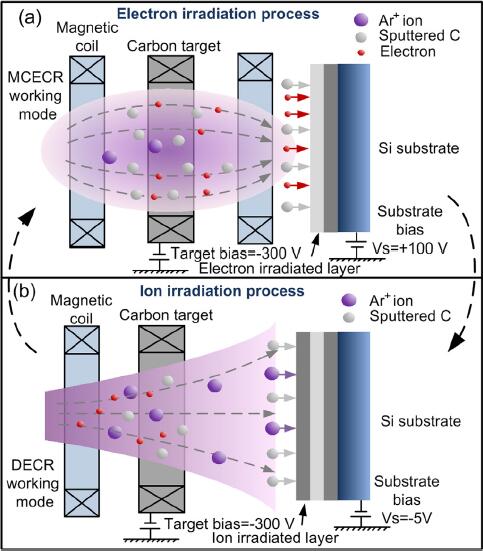

6. Top surface modification of carbon film on its structure,morphology and

electrical resistivity using electron-ion hybrid irradiation in ECR plasma

Surface & Coatings Technology 308 (2016) 50–56

ChaoWang, Cheng Chen, Dongfeng Diao

A two-step electron-ion hybrid irradiation process in electron cyclotron

resonance (ECR) plasma was proposed as a flexible method to obtain carbon film with

low roughness and electrical conductive surface. By the combination of either

electron irradiation or ion irradiation during and after film deposition, two

modes of hybrid irradiation were realized: In i-e hybrid mode, smooth amorphous

carbon film was firstly deposited under ion irradiation, and its electrical

resistivity was reduced from 1.4 to 0.12 Ω·cm−1 after 5-min electron

irradiation. In e-i hybridmode, conductive graphene nanocrystallited film was

firstly deposited, and its surface Ra roughness was decreased from 15.7 to

0.063 nm after 5-min ion irradiation. The top surface structural transition

under electron irradiation in the i-emode were demonstrated by transmission

electronmicroscopy (TEM), Raman spectra, X-ray photoelectron spectroscopy (XPS)

and atomic forcemicroscopy (AFM), and the effective depth of electron irradiation

on carbon film surface were discussed. This study provided a practical route to

themassive production of ultra-smooth carbon filmswith novel nanostructure and

outstanding physical properties for potential applications in nano-machinery

and nano-devices. The hybrid irradiationmethod also expanded theway of plasma

utilization in the fields of film deposition and surface modification, and will

inspire various new films and coatings with improved top surfaces.

method to obtain carbon film with

low roughness and electrical conductive surface. By the combination of either

electron irradiation or ion irradiation during and after film deposition, two

modes of hybrid irradiation were realized: In i-e hybrid mode, smooth amorphous

carbon film was firstly deposited under ion irradiation, and its electrical

resistivity was reduced from 1.4 to 0.12 Ω·cm−1 after 5-min electron

irradiation. In e-i hybridmode, conductive graphene nanocrystallited film was

firstly deposited, and its surface Ra roughness was decreased from 15.7 to

0.063 nm after 5-min ion irradiation. The top surface structural transition

under electron irradiation in the i-emode were demonstrated by transmission

electronmicroscopy (TEM), Raman spectra, X-ray photoelectron spectroscopy (XPS)

and atomic forcemicroscopy (AFM), and the effective depth of electron irradiation

on carbon film surface were discussed. This study provided a practical route to

themassive production of ultra-smooth carbon filmswith novel nanostructure and

outstanding physical properties for potential applications in nano-machinery

and nano-devices. The hybrid irradiationmethod also expanded theway of plasma

utilization in the fields of film deposition and surface modification, and will

inspire various new films and coatings with improved top surfaces.

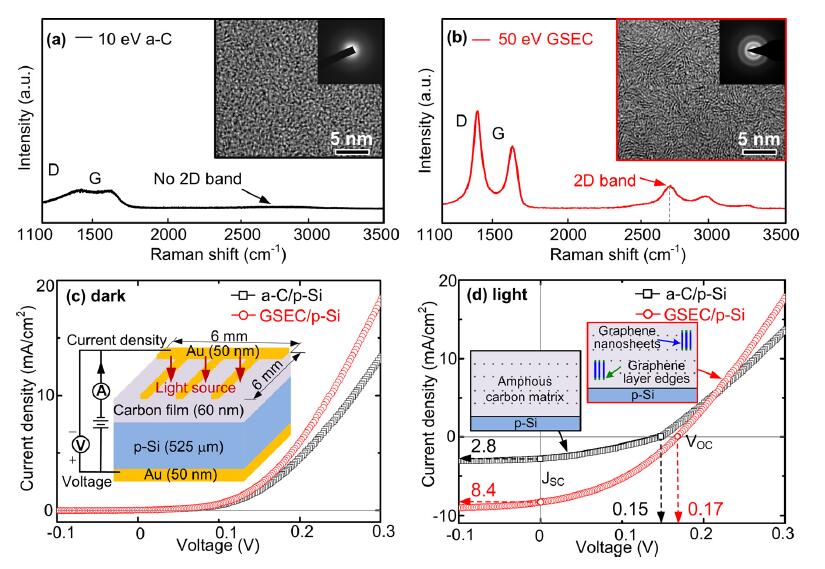

5. Nanosized graphene sheets enhanced photoelectric behavior of carbon

film on p-silicon substrate

Applied Physics Letters 109(2016), 031910

Lei Yang, Gaijuan Hu, Dongqing Zhang, and Dongfeng Diao*

We found that nanosized graphene sheets enhanced the photoelectric

behavior of graphene sheets

embedded carbon (GSEC) film on p-silicon substrate, which was deposited under low energy electron irradiation in electron cyclotron resonance plasma. The GSEC/p-Si photodiode exhibited good photoelectric performance with photoresponsivity of 206 mA/W, rise and fall time of 2.2, and 4.3 ls for near-infrared (850 nm) light. The origin of the strong photoelectric behavior of GSEC film was ascribed to the appearance of graphene nanosheets, which led to higher barrier height and photoexcited electron-collection efficiency. This finding indicates that GSEC film has the potential for photoelectric applications.

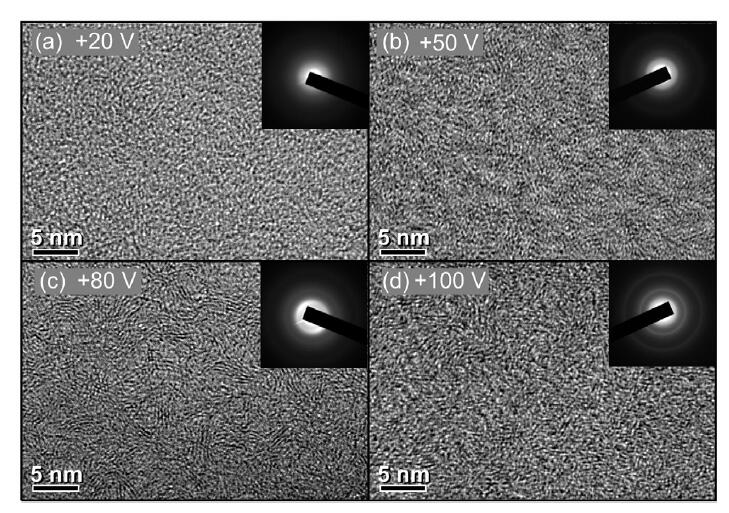

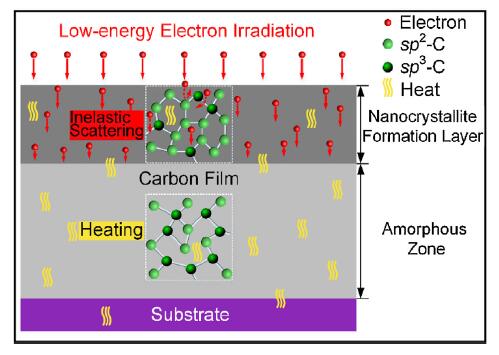

4.Low-energy electron irradiation induced

top-surfacenanocrystallization of amorphous carbon film

Applied Surface Science 384 (2016) 341–347

Cheng Chen, Xue Fan *, Dongfeng Diao *

We report a

low-energy electron irradiation method to nanocrystallize the top-surface of

amorphouscarbon film in electron cyclotron resonance plasma system. The

nanostructure evolution of the carbonfilm as a function of electron irradiation

density and time was examined by transmission electron micro-scope (TEM) and

Raman spectroscopy. The results showed that the electron irradiation gave rise

to theformation of sp2nanocrystallites in the film top-surface within 4 nm

thickness. The formation of sp2nanocrystallite was ascribed to the inelastic

electron scattering in the top-surface of carbon film. Thefrictional property

of low-energy electron irradiated film was measured by a pin-on-disk

tribometer.The sp2nanocrystallized top-surface induced a lower friction

coefficient than that of the original pureamorphous film. This method enables a

convenient nanocrystallization of amorphous surface.

cyclotron resonance plasma system. The

nanostructure evolution of the carbonfilm as a function of electron irradiation

density and time was examined by transmission electron micro-scope (TEM) and

Raman spectroscopy. The results showed that the electron irradiation gave rise

to theformation of sp2nanocrystallites in the film top-surface within 4 nm

thickness. The formation of sp2nanocrystallite was ascribed to the inelastic

electron scattering in the top-surface of carbon film. Thefrictional property

of low-energy electron irradiated film was measured by a pin-on-disk

tribometer.The sp2nanocrystallized top-surface induced a lower friction

coefficient than that of the original pureamorphous film. This method enables a

convenient nanocrystallization of amorphous surface.

3. ECR sputtering and electron/ion alternative irradiation

for multilayer carbon films fabrication with tunable layer thickness

Surface & Coatings Technology 296 (2016), 26–32

Peidong Xue, Lei Yang*, Dongfeng Diao*

In this work, we proposed a method of electron cyclotron

resonance (ECR) sputtering and electron/ion alternative irradiation to formmultilayer carbon filmswith different single layer thicknesses. The soft

electron irradiated layers and protective ion irradiated layers were deposited

as the component layers. The transmission electron microscopy (TEM) and Raman

spectra proved that the graphene sheets structure in electron irradiated layers

could be preserved in multilayer carbon films. We found a rule of the

dependence of the surface roughness, mechanical and tribological properties of

themultilayer films on the single layer thickness. With the decrease of single layer

thickness, the surface roughness decreased and the mechanical and tribological

properties improved notably. The mechanisms of the long wear life with low

friction coefficient were further discussed based on the hardness enhancement

and the cracking length limitation. This work indicated that by decreasing the

single layer thickness, ECR sputtering and electron/ion alternative irradiation

can fabricate films with combined properties of the component materials, which

can be expected for broad nanolayered surface science and engineering applications.

formmultilayer carbon filmswith different single layer thicknesses. The soft

electron irradiated layers and protective ion irradiated layers were deposited

as the component layers. The transmission electron microscopy (TEM) and Raman

spectra proved that the graphene sheets structure in electron irradiated layers

could be preserved in multilayer carbon films. We found a rule of the

dependence of the surface roughness, mechanical and tribological properties of

themultilayer films on the single layer thickness. With the decrease of single layer

thickness, the surface roughness decreased and the mechanical and tribological

properties improved notably. The mechanisms of the long wear life with low

friction coefficient were further discussed based on the hardness enhancement

and the cracking length limitation. This work indicated that by decreasing the

single layer thickness, ECR sputtering and electron/ion alternative irradiation

can fabricate films with combined properties of the component materials, which

can be expected for broad nanolayered surface science and engineering applications.

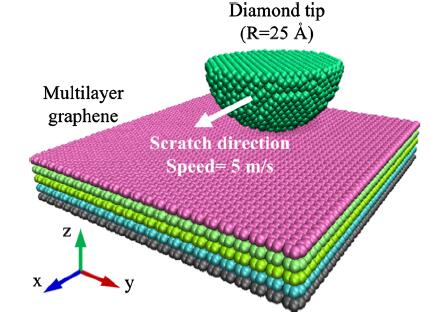

2.Cross-Linking-Induced

Frictional Behavior of Multilayer Graphene: Origin of Friction

Tribology Letters 62 (2016), 33

Lei Yang, Qi Zhang, Dongfeng Diao*

The tribological properties of graphene have attracted

intensive attentions over the past few years. It was found that the frictional

behavior of multilayer graphene was dependent on the multilayer thickness.

However, the origin for such phenomenon is still under discussion. In this study,

the mechanism of the thickness-dependent friction was explored based on molecular

dynamics simulations of the scratching process of multilayer graphene. We found

that the friction coefficient dropped dramatically as the number of layers

increased under the same scratch depth. Further analysis of the graphene

structure variation during the scratching process showed that the amount of the

crosslinking decreased when the number of layers increased, which accounts for

the dependence of the friction coefficient on the thickness. Finally, a novel

chanism was proposed that the thickness-dependent friction of multilayer graphene

was caused by the formation of crosslinking between graphene layers. This study

provides basic understanding of the origin of friction in multilayer graphene.

frictional

behavior of multilayer graphene was dependent on the multilayer thickness.

However, the origin for such phenomenon is still under discussion. In this study,

the mechanism of the thickness-dependent friction was explored based on molecular

dynamics simulations of the scratching process of multilayer graphene. We found

that the friction coefficient dropped dramatically as the number of layers

increased under the same scratch depth. Further analysis of the graphene

structure variation during the scratching process showed that the amount of the

crosslinking decreased when the number of layers increased, which accounts for

the dependence of the friction coefficient on the thickness. Finally, a novel

chanism was proposed that the thickness-dependent friction of multilayer graphene

was caused by the formation of crosslinking between graphene layers. This study

provides basic understanding of the origin of friction in multilayer graphene.

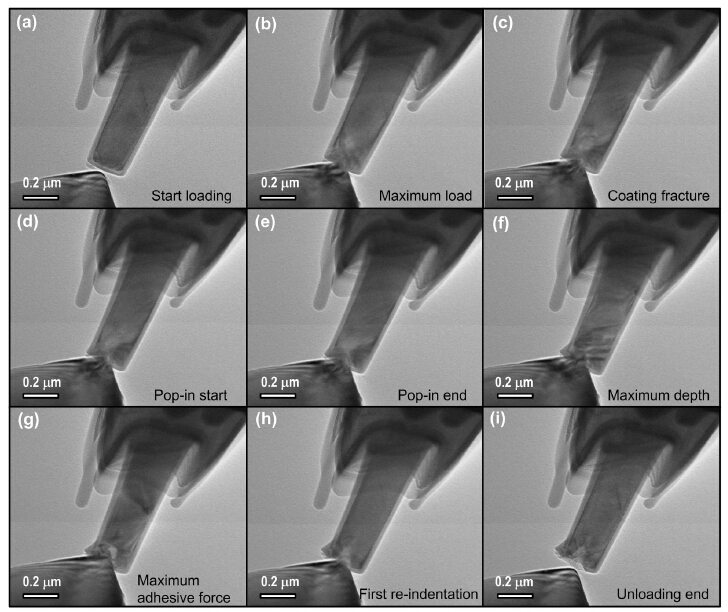

1. The adhesion behavior of carbon coating studied by

re-indentation during in situ TEM nanoindentation

Applied Surface Science 362

(2016) 49–55

Xue Fan,

Dongfeng Diao∗

We report a nanoscale adhesion induced

nano-response in terms of re-indentation during in situ trans-mission electronmicroscope

(TEM) nanoindentation on the carbon coating with silicon substrate. Theadhesive

force generated with nanoindentation was measured, and re-indentation

phenomenon duringunloading with displacement sudden drop and external loading

force change from tension to com-pression was found. The occurrence of

re-indentation during unloading was ascribed to the adhesiveforce of the

contact interface between the indenter and the coating surface. Adhesion

energies releasedfor re-indentation processes were quantitatively analyzed from

the re-indentation load–displacementcurves, and carbon coating reduced the

impact of adhesion for silicon substrate. The adhesion inducednano-response of

contact surfaces would affect the reliability and performance of nano devices.

electronmicroscope

(TEM) nanoindentation on the carbon coating with silicon substrate. Theadhesive

force generated with nanoindentation was measured, and re-indentation

phenomenon duringunloading with displacement sudden drop and external loading

force change from tension to com-pression was found. The occurrence of

re-indentation during unloading was ascribed to the adhesiveforce of the

contact interface between the indenter and the coating surface. Adhesion

energies releasedfor re-indentation processes were quantitatively analyzed from

the re-indentation load–displacementcurves, and carbon coating reduced the

impact of adhesion for silicon substrate. The adhesion inducednano-response of

contact surfaces would affect the reliability and performance of nano devices.